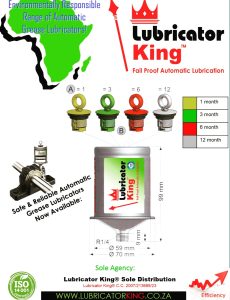

Lubricator King™ have 4 Types and Colour Coded Automatic Lubricators.

Each Pre-Designed to operate for a Set Period and to automatically feed lubricant to your bearings,

equipment or relevant application without any hassle.

Lubricator King™ are filled with different Greases as per client requirements and we have Lubricator King™ Oil Units too.

Why does Lubricator King® have x4 Types of Lubricators ?

TYPE 01 MONTH

FOR BEARING ID/ SHAFT SIZES

100-120MM

3.6 GRAMS OF LUBRICANT PER DAY

Dispensed in a Constant Film

TYPE 03 MONTH

FOR BEARING ID/ SHAFT SIZES

60-100MM

1.2 GRAMS OF LUBRICANT PER DAY

Dispensed in a Constant Film

TYPE 06 MONTH

FOR BEARING ID/ SHAFT SIZES

30-60MM

0.6 GRAMS OF LUBRICANT PER DAY

Dispensed in a Constant Film

TYPE 12 MONTH

FOR BEARING ID/ SHAFT SIZES

0-30MM

0.3 GRAMS OF LUBRICANT PER DAY

Dispensed in a Constant Film

SUPERIOR CHARACTERISTICS UNIQUE TO Lubricator King™

Lubricator King™ is the only Tribology Engineered Automatic grease lubricator we know of that provides a constant Lubrication Film to bearing/application.

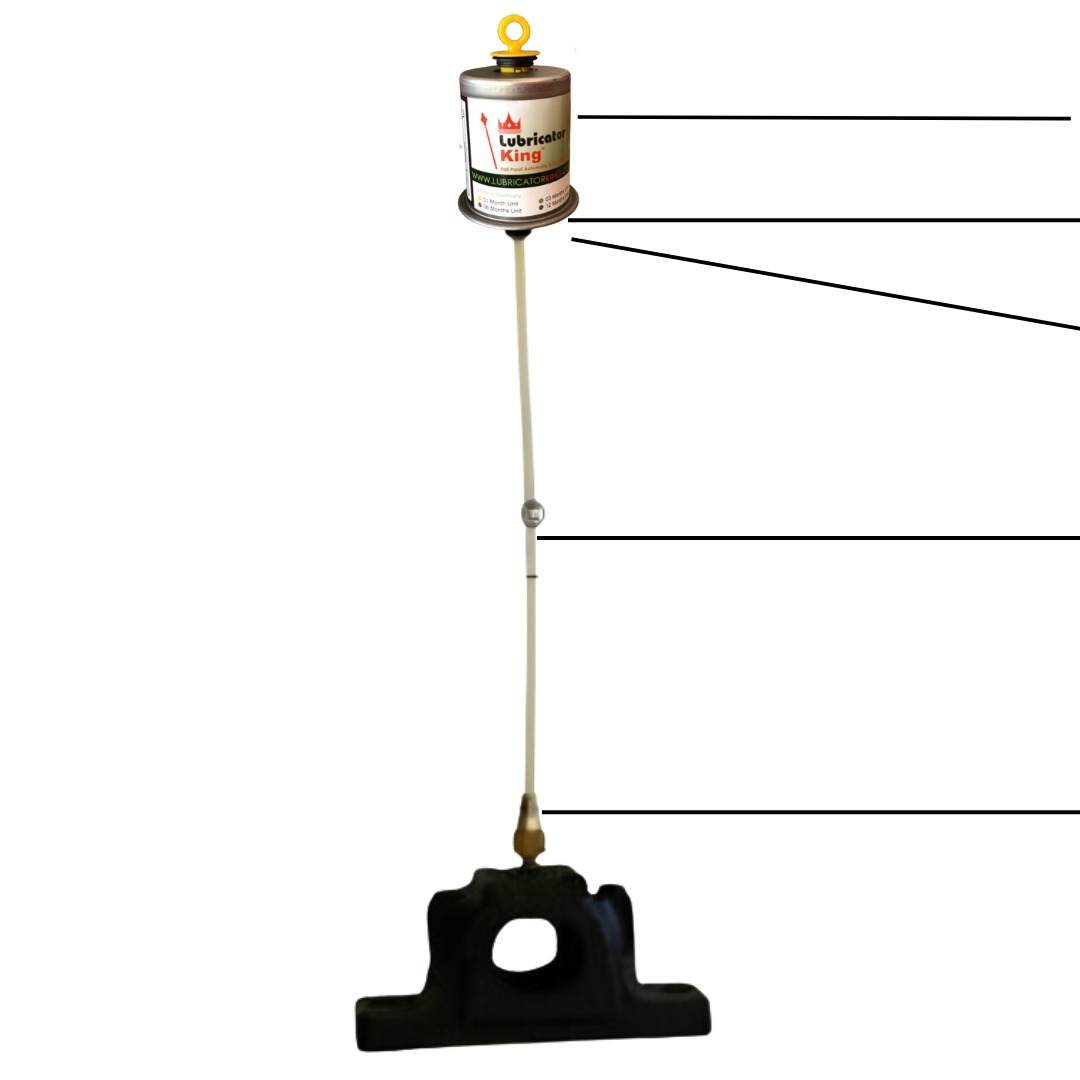

Lubricator King™ can be Mounted IN ANY POSITION, Directly onto the grease nipple or on 1 Meters+ extension lines.

Lubricator King™ has NO electrical, NO mechanical components (which have proven in history to contribute to unreliability), NO Settings (which is complicated) and NO Refilling (which is the definition for Contamination which is a major cause of Bearing Failures in Africa).

Lubricator King ™ has a Zinc steel body making it very robust for Tough areas and also for ensuring that it efficiently handles high (no risk) output pressures and heat with total reliability.

Lubricator King™ have a Strength pressure of 4bar enabling it to deliver Grease via an extension line 1Meter from the actual grease point.

Note: Lubricator King™ having no electrical components, no mechanical components, and no complex settings and having only one moving part, which is the piston pushing down with inner fail-proof chemical expansion once activated.

For all the above reasons Lubricator King™ is extremely- and Superiorly reliable also making Lubricator King™ the Leading Safest Single-Point Lubricator for Underground Operations.

Lubricator King™ is simple to use correctly by any Literacy level employee.

Lubricator King™ operation is trouble free and require no maintenance.

Lubricator King™ are not pre-pressurised and pose NO storage-, environmental- or quality Risk.

Lubricator King™ can be used anywhere; on most applications, both large and small.

Lubricator King™ are not affected by Environmental factors and even works underwater!

Lubricator King™ delivers Proven Performance and also have world-class Mining/Process Operations’ references on its Superior Performance.

Years Established

Satisfied Customers

FAIL-PROOF PERFORMANCE:

Lubricator King® has No Settings.

THUS BECAUSE THERE IS NO ELECTRONICS OF MECHANISM THAT CAN BE BROKEN OR BATTERIES THAT CAN BE FLAT WITH COMPLICATED SETTINGS, LUBRICATOR KING® GUARENTEES FAIL-PROOF RELIABILITY.

- Lubricator King® has No Settings = NO HUMAN ERROR IN SETTINGS SET WRONGLY.

- Lubricator King® has No Settings = DESIGN FEATURE TO ENSURE 100% RELIABILITY

HOW DOES Lubricator King™ FAIL-SAFE LUBRICATORS WORK

As we all know from Science class- Chemical Reactions in sealed conditions have- fixed and Prescribed Outcomes every time.

For all conditions Lubricator King™ performance is pre-determined and Fail-Proof.

Lubricator King™ has NO SETTINGS, but 4 individual Colour Coded Units, Each Lubricator King™ Pre-designed to provide precision Tribology standard’ greasing to bearings or your application.

There are four operating periods (Lubricator King™); 1, 3, 6, and 12 months. After the service time has elapsed, the unit is replaced with a new unit.

Your Lubricator King™ Automatic Lubricator is activated in 1 simple step: by fastening the activator key of your Lubricator King™ until you hear the seal break inside, then fasten completely until the O-ring ontop of the key breaks off leaving your Automatic Grease Lubricator Activated and Tamperproof. Last step is to record change over date on the unit and your Visual Planned Maintenance Tracking Poster Lubricator King Distributions C.C. provide free to all our Customers with every order.

When the seal breaks when you activate your Lubricator King™ : The controlling element is released into Sealed chemicals which reacts to the controlling element, and then there is only 1 Possible Fail Safe Reaction = constant expansion over the designed period the Lubricator King™ is designed for, dispensing a perfect grease-film constantly to your bearing / seal / Equipment etc. regardless of vibration or tolerances.

Satisfied Clients

TECHNICAL GUIDE

CHOOSING YOUR Lubricator King™ TYPE FOR PRECISION GREASING

Your Bearing/Equipment Shaft Size:

Lubricator King™ SA UNIT DESIGNED TO PROVIDE TRIBOLOGY PRECISION AUTOMATIC GREASING

0 – 30 mm shaft size

Type 12 Lubricator King™ (dispense constantly over 12 months)

Colour code KEY -GREY

30 – 60 mm shaft size

Type 06 Lubricator King™ (dispense constantly over 12 months)

Colour code KEY – RED

60 – 100 mm shaft size

Type 03 Lubricator King™ (dispense constantly over 03 months)

Colour code KEY- GREEN

100 – 120 mm shaft size

Type 01 Lubricator King™ (dispense constantly over 01 months)

Colour code KEY – YELLOW

BIGGER than 120 mm shaft sizes

You can continue using Lubricator King™ Efficient- and Fail Proof Technology for shaft sizes Bigger than 120mm shaft size, by using a manifold extension set-up with a single feeding point.

Or you can refer to the Grams of Lubricant you’ll need for that application per day and see table below indicating Grams release per day of each Lubricator King™ and add the Lubricator King units you need together with a single feeding point for your bigger application.

Or you can refer to the Grams of Lubricant you’ll need for that application per day and see table below indicating Grams release per day of each Lubricator King™ and add the Lubricator King units you need together with a single feeding point for your bigger application.

The Tribology Formula to determine how many one month Lubricator King™ units you must couple on the manifold for that bearing is:

The Shaft size in mm / divided by 150 (midpoint of our fastest acting unit) = Number of one month Lubricator King™ units you will couple onto of a manifold with a single feeding point to that Macro bearing.

Type 1 (1 Month)

Grease supply per day grams : 3.6

100 -120mm shaft size : Dispence constantly over 1 month

Type 3 (3 Month)

Grease supply per day grams : 1.2

60 – 100mm shaft size : Dispense constantly over 3 months

Type 6 (6 Month)

Grease supply per day grams : 0.6

30 – 60mm shaft size : Dispense constantly over 6 months

Type 12 (12 Month)

Grease supply per day grams : 0.3

0 – 30mm shaft size : Dispense constantly over 12 months

The Lubricant grams delivery as in above table for each Lubricator King™ Type Per day is for All Average year temperatures in South Africa.

Environmental variations above or below 25’C over a short period of time will have little or NO affect on the overall life of a Lubricator King™ unit. For example, periods of exceptionally hot or cold days is incorporated into the design of Lubricator King™ to still discharge over a month, or 3 months, or 6 months, or 12 months (Ref: Your Lubricator King™ Type used).

For Constant – Extreme Specialised Ambient Temperature Applications in Furnace Plants and Freezing Processes- with a Temperature averaging (over the operating life period of the Type unit) constant above 30’C and Higher or constantly under 10’C or into subzero: the Grease Grams delivery per day- will be higher for constantly extreme high temperature applications and lower for constant extreme freezing temperatures. This is not a limitation for Specialised Clients who wants to apply Lubricator King™ in Specialised Burning temperatures or sub-zero temperatures – as Lubricator King™ Outcome is Still 100% Reliably Fixed and Prescribed and for such Specialised Extreme applications.

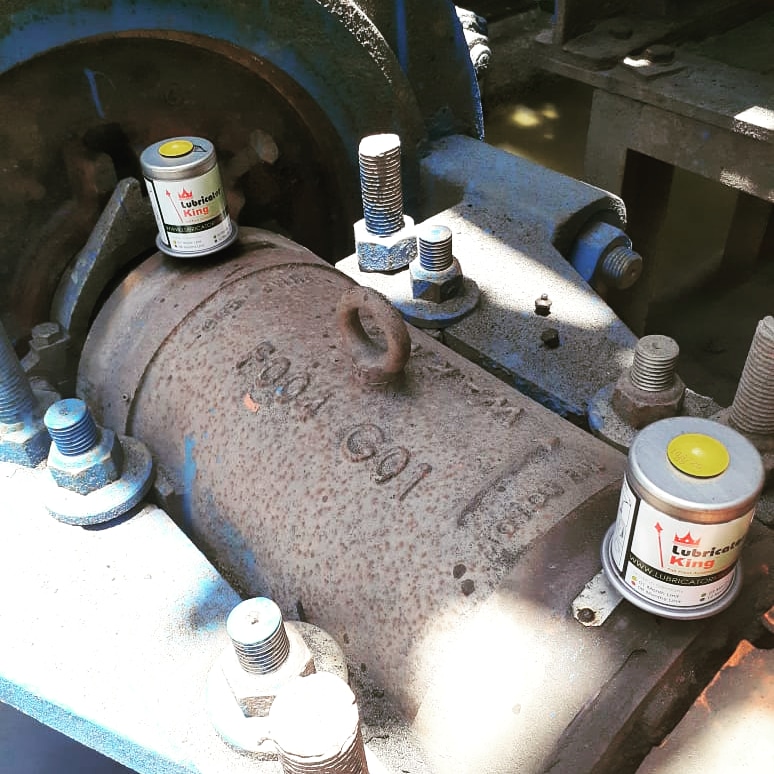

SPECIFICATIONS FOR EXTENSION LINES AND FITTINGS

Steel Support Clip you bolt into nearby structure to hold your Lubricator King Secure & Tamper proof.

Your Lubricator King™ Unit

Airtight Steel fitting

¼ inch female < > 8mm Clip-on Lubricator King™ Unit is screwed into the ¼ inch female side and the Clip-on side of the fitting is clipped onto the 8mm Nylon Extension line.

Extension Line

6mm id. Nylon Tube

8mm id is prescribed as min. id for Grease extension lines of Lubricator King™ . Always ensure to Pre-Grease your Tube & fittings with 1st Installation.We recommend using a Nylon tube (up to 100’C) as you can see the condition of your lubricant.

Airtight Steel fitting

8mm Clip-on < > threaded MALE size

Clip-on side of the fitting is clipped onto the 8mm Nylon Extension line and the Threaded Male side of the fitting is screwed into the GreaseNipple of your equipment.

(All the above fittings remain standard except for this one that we need you to specify to us what is your Grease Nipple Size.)

Extension Line Applications for Lubricator King™ Lubricators:

| Lubricant |

Line length Guaranteed Fail-Proof Lubrication Delivery |

Min. INSIDE diameter of Line |

| Grease |

1 metre |

6mm |

| Oil |

1 metres |

6mm |

Extension Line Applications for Lubricator King™ Lubricators:

| Lubricant |

Line length Guaranteed Fail-Proof Lubrication Delivery |

Min. INSIDE diameter of Line |

| Grease |

1 metre |

6mm |

| Oil |

1 metres |

6mm |

Steel Support Clip you bolt into nearby structure to hold your Lubricator King Secure & Tamper proof.

Your Lubricator King™ Unit

Airtight Steel fitting

¼ inch female < > 8mm Clip-on Lubricator King™ Unit is screwed into the ¼ inch female side and the Clip-on side of the fitting is clipped onto the 8mm Nylon Extension line.

Extension Line

6mm id. Nylon Tube

8mm id is prescribed as min. id for Grease extension lines of Lubricator King™ . Always ensure to Pre-Grease your Tube & fittings with 1st Installation.We recommend using a Nylon tube (up to 100’C) as you can see the condition of your lubricant.

Airtight Steel fitting

8mm Clip-on < > threaded MALE size

Clip-on side of the fitting is clipped onto the 8mm Nylon Extension line and the Threaded Male side of the fitting is screwed into the GreaseNipple of your equipment.

(All the above fittings remain standard except for this one that we need you to specify to us what is your Grease Nipple Size.)

Lubricator king® Oil Unit, Control Valve and Brush

SAFETY & ENVIRONMENTAL STANDARD COMPLIANCE

Using Lubricator King™ Lubricators benefits your Company’s Health, Safety, Environment and Quality Standards by:

- Health of maintenance employees are improved by less contact with petroleum (as in grease / oil) that are a major risk over the long-term contact that have been proven to be the case for manual-greasers.

- Safety is improved as operators are not required to lubricate hazardous areas or lock-out machinery in order to get into confined areas for greasing.

- Lubrication practices being cleaner, Reliable and environmentally responsible; there is no excess lubricant affecting either plant cleanliness or the environment. Environment and cost saving by no longer Over-Greasing but Greasing according to Tribology Standards / Leading Maintenance practices.

- Quality of your Company’s Maintenance Strategy is improved by using Fail-Proof Automatic Lubricator technology & Superior Characteristics.

- We’ve got the following Commitment from Supplier: “Lubricator King™ is manufactured to the highest quality standards. The manufacturer as well as Lubricator King Distributions C.C. is committed to providing the best product of this type together with the best technical support and training of personnel. As part of this commitment we will not introduce any element into the design of Lubricator King™ which can contribute to unreliability, such as electrical or mechanical components, plastic bodies, or by reducing components or using cheaper material including lubricants, to save on production costs.”

- Lubricator King™ Automatic Lubricator is a Low Cost Consumable interpreting into large Value-add for our Maintenance Practice, equipment availabilities, Health / Safety / environmental / +Lubrication standards and overall Efficiency in this regard.

- Lubricator King™ is TamperProof after Activation thus cannot be re-opened and keeping the reaction-expansion sealed

Lubricator King™ Substances is Non-Dangerous pose No danger or risk to- Environment and Humans.

Discarding Empty Lubricator King™ Lubricators:

Lubricator King™ do not use electronics or Lithium batteries. Electronics or lithium batteries used by 99% of other lubricators are radio-active waste and very harmful to the environment and cannot be discarded via normal waste procedures.

Lubricator King™ design provide our Clients with the additional benefit that all empty Lubricator King™ units can be (Safely and Compliant to to ISO 14000 Environmental standards) discarded via normal Industrial waste.

ANY ADDITIONAL TECHNICAL QUESTION / SUPPORT / INFORMATION REQUIRED

Do not hesitate to contact our Customer Hotline available 24hrs

International nr: +2772.0599.611

(see attitional contact information in our Contact Us page)

Contact Us

Commercial Sole Distribution Agency:

Call Us:

Consumer Line : 072 059 9611

Ordering and Logistics: +27 72 059 9611

Email Us:

Physical Address

Lubricator King® are distributed throughout Africa from South Africa:

Emalahleni

Mpumalanga

ZA 1035